Founded in 1994, Yilida is a trustworthy fan manufacturer in the global market. As a listed company (stock code 002686) supervised by Zhejiang provincial SASAC (State-owned Assets Supervision and Administration Commission), Yilida always strives for constant growth and improvement to provide high quality commercial & industrial fans and excellent services to satisfy all needs for air conditioning and building ventilation applications. At Yilida we have made a firm commitment to innovation and continually developing intelligent high-efficiency fan motors, and do not consider ourselves as a traditional fan manufacturer but far more as a fan and intelligent motor system integrator. Our aim is to achieve the brand concept of "smart air".

Passionate for its business, Yilida has independently developed New EC technology that is well-known in the domestic market, and successfully launched permanent magnet brushless motor which can be used in more applications in comparison with conventional fan motors. The motor features of less vibration, low noise level, high efficiency and intelligence enable the demands of energy saving and emission reduction to be significantly achieved.

Whether it is traditional fans or energy-efficient fans, Yilida can independently develop and manufacture all parts of fans, motors and control systems. By combining fans, EC motors and integrated inverters, Yilida is able to provide complete energy saving fan solutions for customers' needs of refrigeration units and air conditioning terminal units.

Enhanced Energy Efficiency of Fans- Most Yilida’s products are certified by AMCA for air performance, sound and energy efficiency;

- R&D achievement of multi-arc backward curved blade, efficiently improving the efficiency of fan impeller;

- Reduced velocity design of the fan inlet cone and optimized gap existing between air inlet and rotating impeller, further improving fan efficiency;

- The adoption of advanced vaneless diffusion technology helps in minimizing air losses, resulting in higher fan static pressure;

- Development of advanced DC brushless motor, enabling the efficiency of small ventilation equipment to be greatly increased;

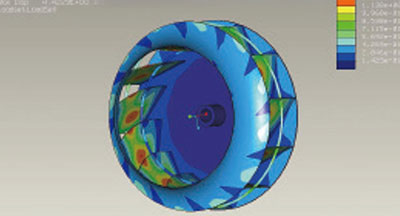

- Adopting finite element analysis software to analyze the natural frequency of fan impeller;

- Reducing fan noise using computational fluid dynamics (CFD) and computational aero acoustics (CAA) simulations;

- Exclusive design of arc blades results in efficient reduction of noise;

- Rational design of centrifugal fan scroll housing provides less sound level;

- Utilizing dynamic balance control system to ensure that the fan runs smoothly with reduce noise;

- The reliability and stability of fans and motors are secured through structural analysis and mechanical analysis;

- Regularly tested by domestic authoritative bodies and subjected to AMCA testing procedures;

- The dynamic balance reaches international standards DIN/ISO 1940 and AMCA204-05 G6.3 grade;

- Using high quality parts from world's renowned brands such as NSK/OPTIBELT/ABB, ensuring the smooth operation of fans and motors;

- Natural frequency measuring system is used to precisely measure and analyze the mechanical parts;

- Destructive testing of fan impeller to ensure the reliability and durability;

- Automatic digital X-ray non-destructive testing system is used for in-line testing of castings;